Lubricating

Excellence

Exclusive partner of Emarat Petroleum

Afrilube oils have been proven to be the best in the industry.

Everywhere

Why settle for genuine engine oil.

Choose the best

Afrilube Product

Hydraulic Oils

Lubricant Manufacture and Supplier Across Globe!

AFRILUBE offers a full range of hydraulic oils, including zinc-free hydraulic oils, zinc-containing hydraulic oils, synthetic hydraulic oils, and hydraulic oils with detergency properties. They also have fire retardant hydraulic and food grade hydraulic oils. These oils are specially formulated to allow rapid shedding of water, quick release of entrained air, and prevention of rusting in hydraulic systems.

Lubricants

Lubricant Manufacture and Supplier Across Globe!

Industrial Gear Oils

AFRILUBE provides gear oils specifically designed for transmissions, transfer cases, and differentials in automobiles, trucks, and machinery. These oils have a higher viscosity to better protect gears and ensure the transfer of lubricant throughout the gear train.

Slideway Oils

Slideway oils are intended for machine tool slides, gear lubrication systems, and hydraulic systems in machine tools. AFRILUBE’s slideway oils have excellent anti-corrosive properties and adhesion to metal surfaces, making them suitable for preservation of stored equipment.

Turbine Oils

AFRILUBE recognizes the increasing demands placed on lubricants used in power stations and gas/steam turbines. They offer long-life turbine oils with outstanding thermal oxidation stability, water and air release properties to meet the requirements of modern turbine systems.

Transformer Oils

AFRILUBE supplies transformer oils or insulating oils that are stable at high temperatures and have excellent electrical insulating properties. These oils are primarily used in oil-filled transformers, high voltage capacitors, switches, and circuit breakers.

Optimize

Lubricants Range

AFRILUBE aims to meet the diverse lubrication needs of industries and provide effective, high-quality lubricant solutions

Heat Transfer Oils

AFRILUBE offers heat transfer oils that efficiently transfer heat in various applications.

Chainsaw Oils

AFRILUBE provides mineral-based lubricating oils specifically blended for agricultural chains and other chain applications in chainsaws.

Chainsaw Oil is a mineral based lubricating oil blended from specially selected base oils, anti-wear and tackiness additives to make it suitable as a premium quality oil for use in agricultural chains, and other chain applications.

Rockdrill Oils

AFRILUBE supplies rockdrill oils suitable for lubricating rock drilling equipment.

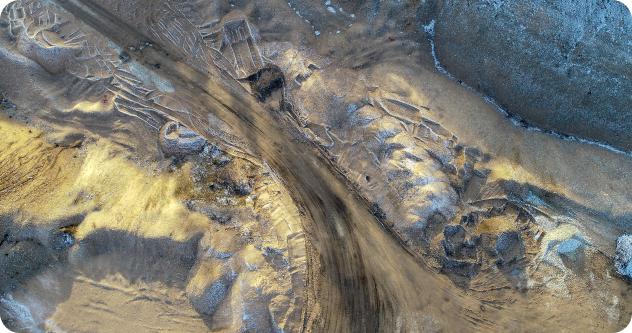

Mining Lubricants

AFRILUBE understands the critical role of lubricants in mining operations and offers specialty lubricants for both underground and surface mining purposes.

Metal Working Fluids

AFRILUBE offers a range of metal working fluids including cutting oils, corrosion preventatives, forming, quenching and pressing oils, and neat cutting oils.

These fluids are designed to enhance tool life, sump life, and cost-effectiveness in metal manufacturing industries.

Fluids

Working Metal Fluids

AFRILUBE offers a range of metal working fluids including:

01

Cutting Oils

Our Cutting Oils range offers a full and comprehensive selection of soluble oils from a mineral, semi synthetic to full synthetic coolants

02

Corrosion Preventatives

They will reliably protect bare steel surfaces whilst being easy to apply they are also easy to remove.

03

Forming, Quenching and Pressing Oils

One of the demands placed on the modern day metal forming lubricants is its cost effectiveness.

04

Neat Cutting Oils

Our heavy duty low emission oils provide effective manufacturing efficiency using advanced low emission technology. Lower misting, lower evaporating oils.